The in-line filter segments transportation system of Solaris allows a stable combining routine.

Filter technology for conventional and innovative products

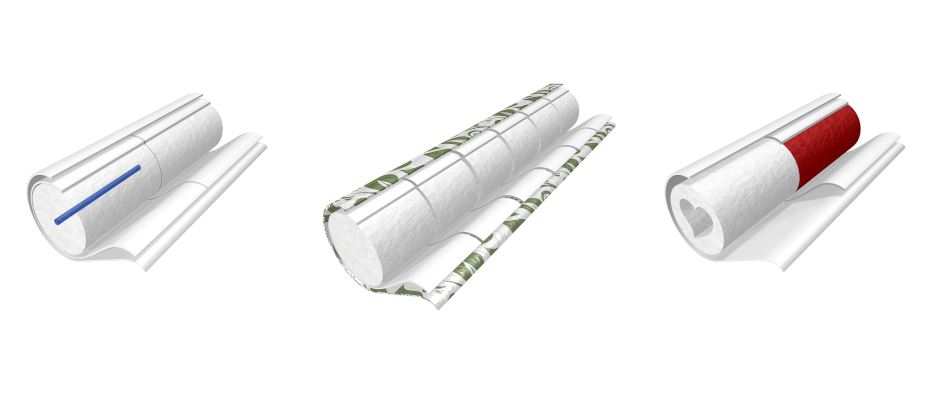

The Solaris technology can be used for conventional products, as well for unique and innovative products, like heat-not-burn products. Depending on customer’s and product’s needs, Solaris comes in different configurations, like Solaris Dual, Solaris Triple and Solaris Quadruple. All configurations are designed to combine semi-finished filters into finished filter products.

Modular design for optimal flexibility

Each module is individually controlled by its own servo drive, enabling to completely configure the segment order of the transport chain. This provides optimal flexibility and allows instant changes. The modules can easily be connected in a different sequence when required. Once connected to the main combining unit, each module is instantly ready for production.

Extend functionalities for new unique products

Solaris can easily be extended with new functionalities for introducing new, unique products into regular production. Each module is completely self-sufficient in terms of control, equipment and production capabilities. This provides the possibility of creating many dual, triple and quadruple segment specifications on a single machine.

Fast changing segments in filters

The design of each Solaris module is based on a plug-and-play-philosophy, which ensures fast and easy conversions. This means that exchange can be completed in a fast way. Changing some of the segments, patterns or sequences, can be done from the operator screen without requiring mechanical changes.

Facilitating product development in filter combining

The machine’s modular construction and fast brand changeover capabilities facilitate not only mass production but also product development.

Solaris extensions

ITM has developed a range of extensions for Solaris, for example for combining filters with non cuttable objects (NCO) or filling cavities with granules, powders or objects.